Calibration

Air Quality monitors should arrive calibrated from every manufacturer.But the problem is how to ensure that the data is of good quality after 6, 12, 24 months.The requirement for continuing both the data accuracy (absolute error) and the precision (repeatability) is very important with low cost sensors.To ensure that your monitor continues to provide reliable data, you must understand the calibration requirements.

A simple statement to calibrate every 6 or 12 months is unfortunately too simple. We need to understand two important truths:

1. The BuiltAir IEQ Monitor includes both physical and chemical sensors:

- Physical sensors are fabricated using semiconductor processes and record physical or electronic changes such as strain, light absorption and scattering, capacitance and resistance; they are very stable over time and any drift is normally just an offset shift.

- Chemical sensors require the air to chemically react with the sensor. These sensors lose sensitivity with time and their offset (baseline) will change, depending on the environment they are sensing.

2. There are two different approaches to calibrating an indoor air monitor:

- Calibrate a monitor by applying external controlled conditions such as gas, particles and temperature changes, in a controlled environment such as a test lab. This standard method is unfortunately expensive and time consuming, defeating the advantage of low cost monitors.

- An alternative calibration method, using a network of monitors is becoming the de facto method for calibrating outdoor AQ networks; the list of references below explain more. The BuiltAir IEQ Montors uniquely create an indoor network of monitors which can be easily co-located and then record synchronised calibration data for simple remote statistical analysis.

Are you calibrating physical or chemical sensors, individually or as a network? The table below summarises what is possible.

| Single Monitor | Monitor Network | |

| Physical Sensors | Co-locate with a reference instrument. Baseline calibration simply requires ambient conditions Gain calibration requires a controlled environment, but can be less frequent (24 months). | Co-locate and datalog the network for 1-2 hours; remotely analyse for baseline precision calibration. Add a reference instrument to the network for improved baseline accuracy. Baseline calibration simply requires ambient conditions. Gain calibration requires a controlled environment, or an environment with changing conditions, but can be less frequent (24 months). |

| Chemical Sensors | Co-locate with a reference instrument. Baseline calibration simply requires ambient conditions but must be clean. Gain calibration is required and requires a controlled environment. | Co-locate and datalog the network for 2-24 hours; remotely analyse for baseline precision calibration. Add a reference instrument to the network for improved baseline accuracy. Baseline calibration simply requires ambient conditions. Gain calibration requires either a controlled environment or an environment with changing conditions. |

The BuiltAir© SensorNet© (Monitors plus Cloud) is designed for efficient and transparent calibration:

- Monitors are removed from their selected locations and co-located in a stable environment for calibration. Their small size and long battery life allow easy co-location of the entire network in one location for calibration. Define in the BuiltAir Cloud all of the monitors as a single Session and start recording for at least one hour. Select 15 or 30 second logging interval.

- When the Session has finished, define a Dataset, but ignore the first 15 minutes of data, allowing time for the monitors to stabilise. Wait while the Cloud processes the Dataset.

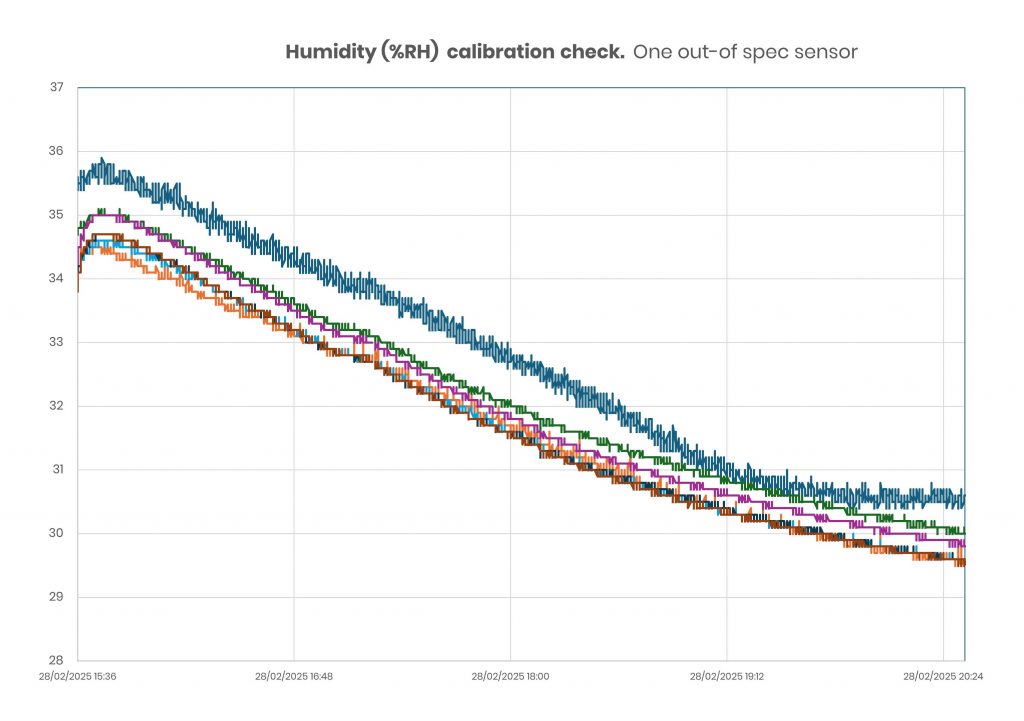

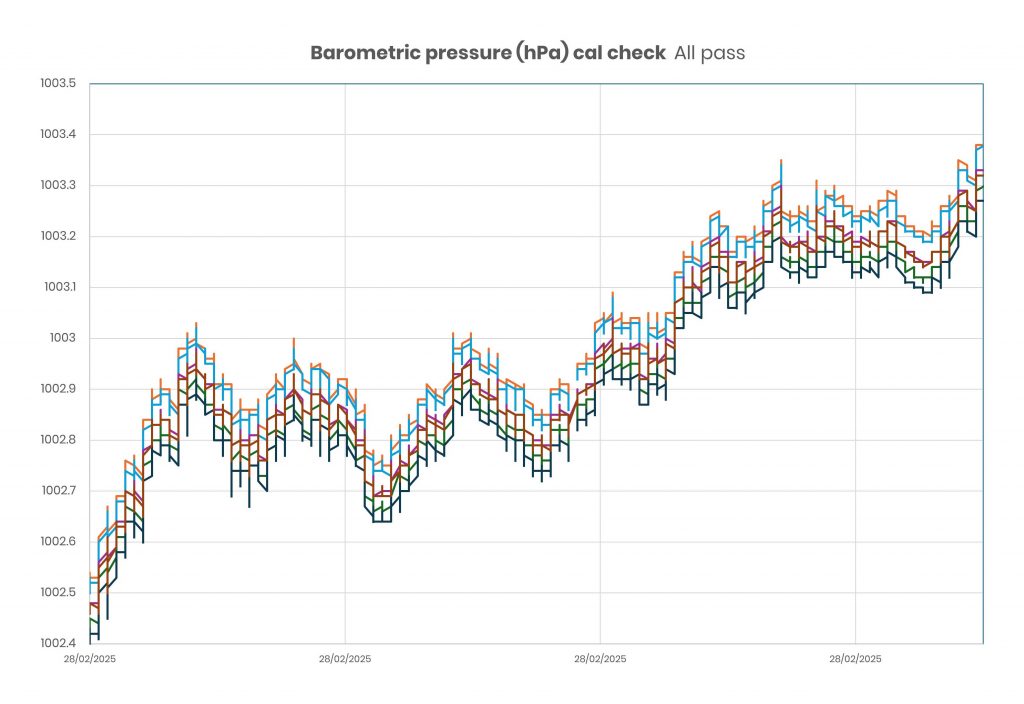

- Review the data using the Gallery option. Any outliers or sensors that have drifted will be obvious. See attached plots as examples. Also, look at the Heatmap: you will see the variance from the mean for each measurement in each monitor.

- Then decide whether the precision of your network is within your requirements or select the Update Calibrations option and add an offset for a specific measurement for a specific monitor. The Calibration Table can be downloaded for transparency.

- You have just calibrated your entire network for baseline drift, the main source of error in IAQ/IEQ monitors. The assumption is that the mean of the measurements is accurate. If you add a reference instrument to the co-located monitors then you can confirm that the mean of the measurements is also accurate.

- There is no need to employ machine learning (ML) or AI for these calibrations, just simple statistics.

- Gain correction can usually be ignored for physical sensors and the only chemical sensors in the IEQ Monitor that show gain drift are the NO2 and VOC sensors. The RH sensor, although a chemical sensor, shows very little gain drift over years of use.

Reference instruments for NO2 calibration are typically chemiluminescent gas analysers or a “golden transfer standard”. Physical sensor reference instruments for field calibration can be instruments that have been recently calibrated to ASTM, CEN or ISO standards.

Examples of data from the BuiltAir© Cloud are shown below.

The Relative Humidity data looks good for these 17 IEQ monitors. They are all within ±1%RH of the mean.

Sixteen Monitors are within specification, but A30093 (black) is outside of the ±8 Pa specification and a 20 Pa offset should be added to return it to specification. A30097 (blue) is at the edge of its specification and an offset correction of 7 Pa can be added to improve precision and accuracy.

Box and whisker analysis is also provided for each sensor. This example shows the statistics for the RH graph above, showing performance for all 17 BuiltAir© IEQ monitors.

References

Modelling and Determining Correlations in Sensor Networks, Gertain Kok et al, J. Measurement: Sensors 38 (2025) 101793 doi.org/10.1016/j.measen,2024101793

A Scalable Calibration Method for Enhanced Accuracy in Dense Air Quality Monitoring Networks, Winter, Cohen et. al, J. Environ. Sci. Technol.(2025) doi.org/10.1021/acs.est.4c08855

Co-Location Study of 87 Low-Cost Environmental Monitors: Assessing Outliers, Variability, and Uncertainty, A , S Manu, Buildings 2024, 14, 2965. doi.org/10.3390/buildings14092965

Use of networks of low cost air quality sensors to quantify air quality in urban settings J. Atmos. Sensors Sept 2018 doi.org/10.1016/j.atmosenv.2018.09.030

Development of a baseline-temperature correction methodology for electrochemical sensors and its implications for long-term stability, O. A. Popoola,R. L. Jones,et al. Atmospheric Environment, vol. 147, 330–343, 2016 dx.doi.org/10.1016/j.atmosenv.2016.10.024