Indoor Air Quality Monitoring: Does It Matter?

Monitoring indoor air quality (IAQ) and indoor environmental quality (IEQ)is important because people spend 80–90% of their time indoors, and poor air quality affects our health, safety, comfort, and performance. Homes, public buildings, stations, and vehicles each present different risks, but the reasons for monitoring the air are similar.

Poor IAQ and IEQ can lead to:

- Headaches, fatigue, and irritation of eyes, nose, and throat

- Worsening of asthma and respiratory conditions

- Increased risk of cardiovascular and long-term health issues

- Greater vulnerability for children, older adults, and those with existing conditions

What Do We need To Consider?

Measuring air quality helps identify pollutant sources, ensure regulatory compliance, and guide interventions that protect the public’s health and improve wellbeing. It is particularly important in urban areas, near transport hubs, and in sectors like construction and manufacturing where emissions can be higher than average. Air pollution has now outpaced smoking and high blood pressure as the number one global health risk (WHO).

Consider both indoor air quality (IAQ) and indoor environmental quality (IEQ).

IAQ:

- CO2 (breathing → ventilation indicator)

- Particulate Matter (PM1 PM2.5, PM10) (traffic, cooking, DIY, hobbies, vacuuming)

- Nitrogen Dioxide (NO2) (gas cooking, fireplaces, traffic)

- Ozone (O3) (similar to NO2, oxidises VOCs and attacks our lungs)

- Volatile organic compounds (VOCs) (cleaning fluids, new surfaces, cooking)

- Carbon Monoxide (CO) (faulty gas boilers, vehicle exhaust)

- Biological contaminants (mould spores, bacteria, viruses)

IEQ:

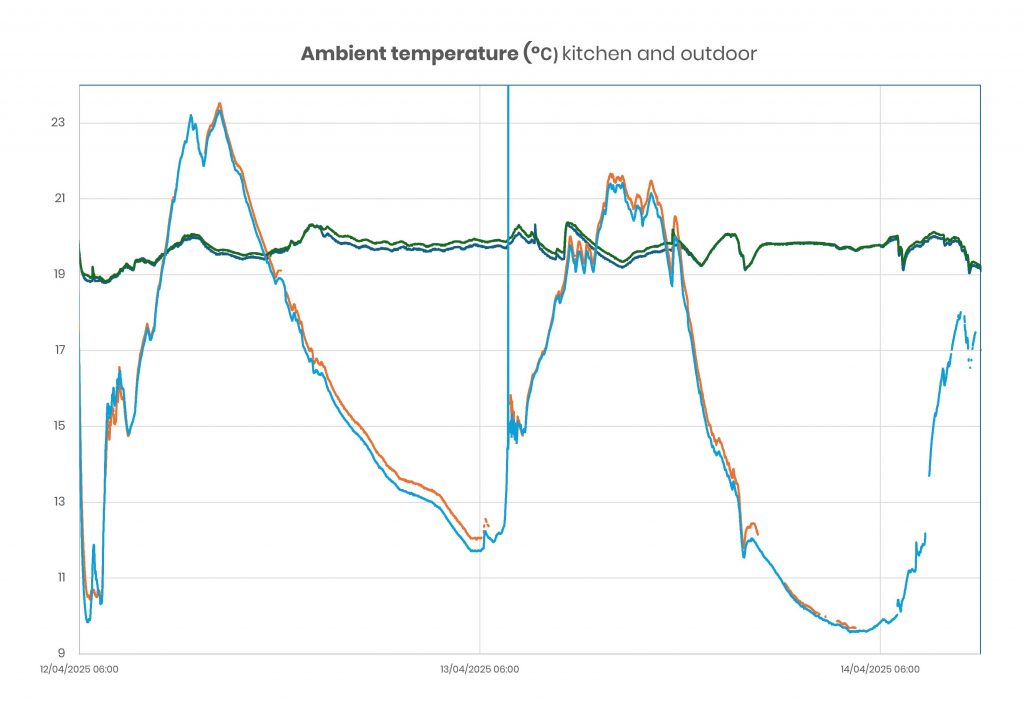

- Ambient temperature

- Radiant temperature (radiators, windows, hot equipment)

- Relative humidity (low humidity=dry skin; high humidity=mould growth)

- Barometric pressure (drives airflow between zones)

- Local airflow (identifies drafts and dead space with no air circulation)

Commonly Used Guidance and Standards

Before doing any monitoring, it is important to first read the guidance and standards for indoor air monitoring:

- ASHRAE 55 and ASHRAE 62

- CEN 16798-1

- ISO16000 series of IAQ and IEQ standards

- National and local building ventilation regulations and advice

Applications Across Sectors

Indoor air monitoring is relevant to a broad range of users.

Local councils and housing associations should assess buildings for the factors that give rise to damp or mould formation. They should also understand the air exchange rate by monitoring CO2 as a tracer gas. The presence of indoor pollutants (particulates, NO2 and TVOCs) can be easily monitored to map and build a picture of areas and zones that have particular issues. School ventilation systems are frequently old or poorly maintained, so optimising what you have is important.

While workplace exposure monitoring traditionally relines on MDHS monitoring within the breathing zone, there are local and national requirements for area monitoring, specifically to understand any pollutant peaks which can occur when people move through the work area, which spot checks could easily miss.

BMS – Building management systems control ventilation within a building by monitoring temperature, relative humidity, airflow and carbon dioxide.

See below for further information.

Housing, schools, public buildings: Moisture, Mould & Building Health

Poor ventilation and high humidity can lead to condensation, damp, and mould growth,  which can cause serious health problems – particularly in residential and social housing. Bacterial growth can also damage the building walls, increasing maintenance costs.

which can cause serious health problems – particularly in residential and social housing. Bacterial growth can also damage the building walls, increasing maintenance costs.

Comfort & Wellbeing

IEQ is closely linked with thermal comfort, noise, and light. Even if the air is “clean”, poor temperature control, drafts, or excessive noise can cause discomfort and complaints. Poor lighting strains the eyes.

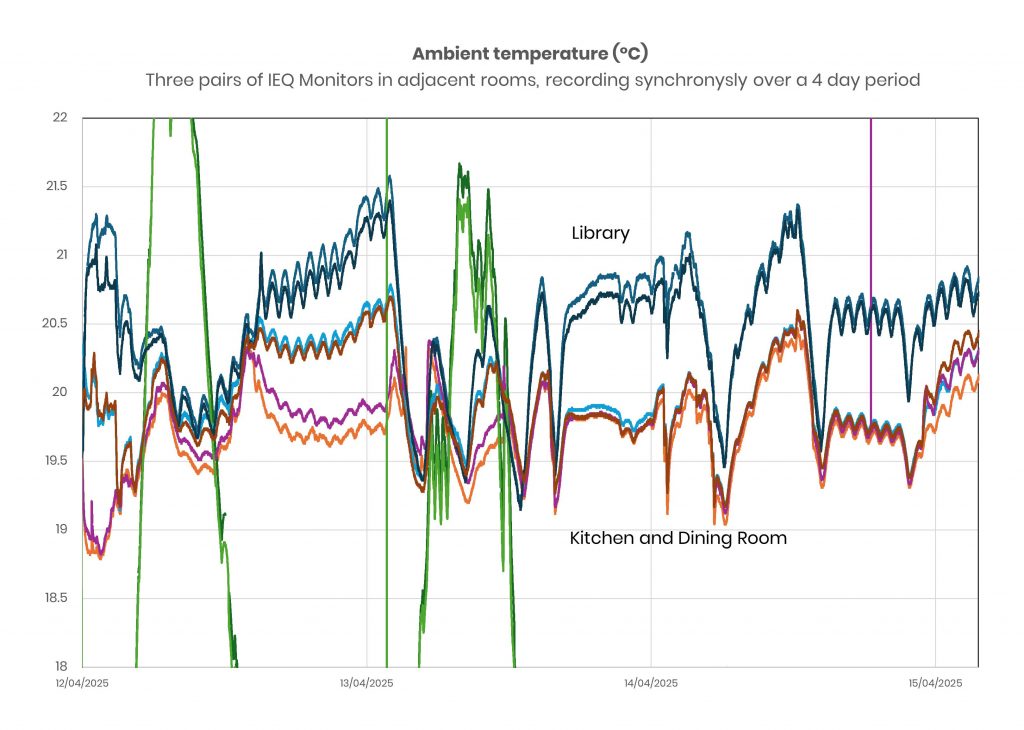

Zonal Mapping & Scalability

IEQ Monitors can be deployed as a network to create detailed environmental maps across several rooms, floors, or even entire buildings. Network mapping is necessary for complex spaces with varying ventilation and usage patterns. Competitors offer only standalone sensors with no insight into the overall built environment .

Workplace Exposure and Zone Monitoring

Workplaces can have specific airborne hazards that need to be monitored and controlled, and the three most common pollutants are considered below. Contact us to discuss keeping your workers healthy and safe.

Particulates (PM10, 2.5,1)

- Useful for identifying dust-generating processes, material handling, or infiltration from adjacent zones

- Evaluate local exhaust ventilation (LEV) effectiveness

- Determine accumulation during shift changes or cleaning activities

- Interpretation: Understand the ventilation differences between zones and identify polluting sources and poor airflow distribution.

Nitrogen Dioxide (NO2)

- Relevant where combustion sources are present, including gas heaters, forklifts, and plant equipment

- Useful for identifying combustion product build-up in poorly ventilated or enclosed areas

- Supports investigation of intermittent emission events

- Provides records of compliance with local and national workplace requirements

- Interpretation: Pollutant peaks frequently align with equipment use or heating cycles, indicating control or ventilation issues.

Volatile Organic Compounds (VOCs)

- TVOC is the Total concentration of all VOCs

- Vapours and fumes arise from solvents, coatings, adhesives, fuels, or off-gassing of new building materials, furniture and soft furnishings

- Useful for trend monitoring but the sensors cannot measure specific VOCs

- Helps identify unwanted effects of process changes

- Interpretation: Sudden VOC increases may indicate spills, process deviations, or inadequate ventilation.

BMS (Building Management System) integration

BuiltAir provides a high-resolution, API-accessible data stream of indoor air quality and environmental parameters, enabling seamless integration with modern Building Management Systems and analytics platforms. Through its zone-based architecture, multiple devices aggregate spatially relevant data across rooms, floors, or entire buildings, supporting advanced control strategies for HVAC, demand-controlled ventilation, and fault detection. High-accuracy sensing, low-latency data availability, and configurable threshold triggers allow BMS platforms to act on measured conditions rather than inferred values, improving control stability, energy efficiency, and compliance reporting within interoperable, software-led building ecosystems.

Data

Data from the entire network can be viewed and monitored with the BuiltAir graphical user interface (GUI) or data dashboard. This also provides the opportunity to set sampling rates and alarm trigger levels. You can also use the BuiltAir IEQ Monitor as a simple stand-alone monitor, capable of logging up to six weeks on the internal battery and storing up to 500,000 data records.